-

Raw materials

Raw materialsThe fabric quality depends mostly on the yarn employed, that is why the research of the perfect raw material is an essential pillar in textile creation. Our attention to detail leads us towards the best quality cotton, the finest wool, the softest Kashmir, without neglecting the best quality of the other fibres we employ, like alpaca, mohair, silk and viscose.

-

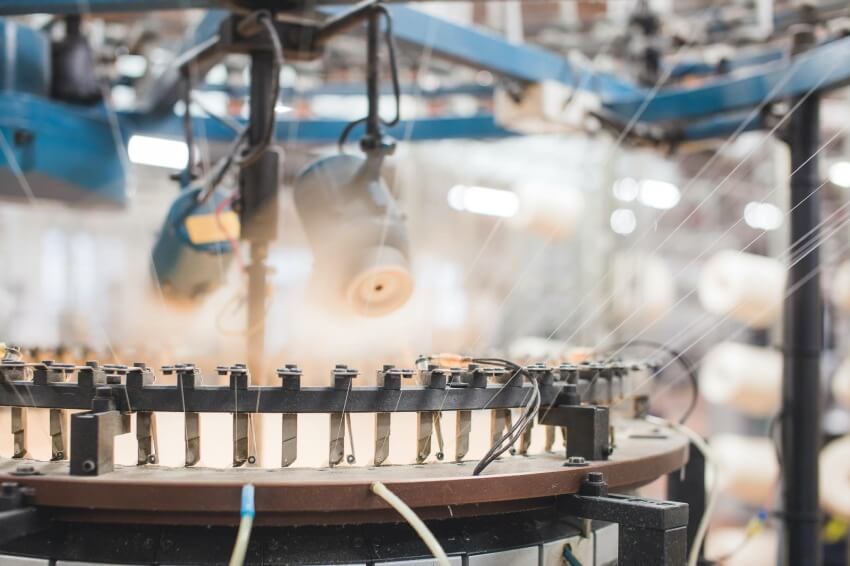

Weaving department

Weaving departmentIn our weaving department there are more than 30 circular looms, doubleknit machines that are able to weave jacquard, fleece, terry cloth from the thickest to the thinnest ones, so that we can offer a wide range of selections to our customers. Our weaving department is constantly increasing in dimension in order to satisfy the permanent needs of the market, but also to create new and valuable plots.

-

Laboratory

LaboratoryIn our in-house laboratory are carried on important activities, like dyeing solutions project and preparation, dyeing tanks scheduling, fastness and quality analysis on yarns and fabrics. The work of this department is really important for us, because we care to operate in the full respect of all qualitative and eco-toxicological parameters.

-

Quality control

Quality controlThe ancient and noble art of dyeing is the most creative field in textile industry because it can give fabrics attractive nuances and charming shades. Our dyeing department which works mostly on cotton fabrics and yarns - allows us to perform various activities, like scouring, washing by enzymes and piece dyeing, which is carried out thank with the exclusive employment of reactive dyes. Drying and sanfor ironing are at the end of the internal production chain, hence they give the fabrics their final look.

-

Samples department

Samples departmentThis is one of the most dynamic departments in our business reality, a place in which our customers request for samples are managed and our collections are put together and prepared to be taken to the several annual textilies fairs around the world.

-

Dyeing department

Dyeing departmentOnce at this point it begins the last and fundamental phase of the chain: quality control. Even thought several tests are performed during every stage of production, this is when our fabrics are recognised as suitable or not to be sent our customers. Our skilled workers put fabrics through an actual scanner by means of fabric inspection machines, with the aim of cleaning remaining impurities and creating fabrics that respect our high quality standards.

Production chain

Production chain

What we do

Our fabrics are conceived and made in our plant located in Occhieppo Superiore, near Biella.

In order to best meet the requests of our customers, we offer a wide variety of fabrics, from simple jersey for t-shirts and mercerized interlock for blouses to fleece and doublet for men’s jackets, from stitched jersey for soft women’s dresses to technical fabrics and terry cloths.

The variety of our structures is reflected in the yarns used to produce our fabrics, so that we can create a triumph of elegance for every men and women.